Quality is at the forefront of our JMV's business model and a high priority is given to see that we produce and sell high-quality products. This is even more

so when it comes to our flagship product; the Vibro Mesh.

Consequently, JM Vassallo operates its own in-house testing laboratory to ensure continual and sustainable quality-driven production techniques. This goes hand in hand with our high internal quality and production control standards.

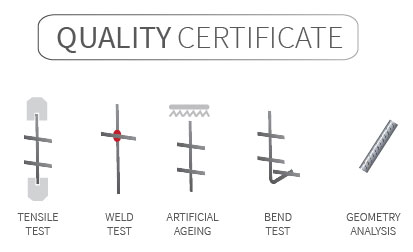

Samples are taken at random from each batch that is produced at JMV and these samples are first aged so as to investigate the sample's quality as it ages. After aging is complete; the sample is duly marked; its weight per metre compared to set EU and ISO standards and a geometrical analysis; again compared to set EU and ISO standards is performed. Then the subject is subjected to tensile and weld tests both of which have to satisfy EU and ISO standards to be given the go ahead and to be sold to JMV's customers. The last step in the process is bending the sample to a 90 degree angle where it is then inspected for any cracks.

It is only after the sample has gone through these vigorous and meticulous tests that the batch is approved and sold to the customer. Thus when one purchases JMV products one can have peace of mind that the products are of high quality and that they are completely safe.