Here at JMV we take pride in what we offer. One of the core products which consolidates our company’s solid underpinning is our steel reinforcing meshes. Quality control and traceability form an integral part of our manufacturing and processing operations. Electro-welded steel reinforcing mesh is not just a manufacturing process but requires constant monitoring and an effective system to identify any non-conformities.

New Mesh Welding Plant

The installation of the new mesh welding line has brought significant changes and a number of advantages to our customers. This new line offers the possibility to produce electro-welded steel mesh with wire diameters ranging from 5mm to 12mm in both directions. The short time required to change wire diameter, spacing and panel dimensions makes it economically feasible to supply customers with orders both in small and large quantities in an efficient manner. The new facility also allows us to offer a wider and more flexible range that can be considered at the design stage.

Innovation using the latest technology

Our Vibro Mesh is produced from high quality high ductility steel, where properties are guaranteed with stringent checks performed throughout the whole manufacturing cycle. The new plant offers several exciting advantages which are not only beneficial to mesh design but also aid in minimising waste by reducing the use of excess steel material.

The possibility of varying the diameter of the wires, meshes and size of panels according to the design requirements gives great versatility and flexibility. Moreover, our clientele can also benefit from significant cost savings.

Some applications include:

- Mesh panels for casting in-situ and prefabricated elements that are designed according to structural requirements and operating site conditions.

- Bi-directional meshes

Electro-welded meshes with variable tails on both edges to ensure proper transversal and longitudinal overlapping of panels with a reduced thickness, used mainly in reinforced concrete walls and monolithic floors.

- Panels with irregular transversal wire spacing.

- Mesh for pillars and ring beams

A reinforced technology that creates a pre-assembled system of stirrups for pillars, beams or any shaped element

- Inclined, L-shaped and segmental meshes

- Meshes with double welded transversal wires

- Meshes used for structural footings / Pile Caps

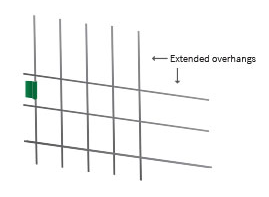

- Fabric Laps using made-to-measure extended (flying-ends) overhangs.

Meshes with Flying-end overhangs allows for congestion-free lapping of welded fabric, minimising material waste, improving site laying cycles and ensuring adequate concrete cover.

Mesh Typology

Over the last decade, we have seen a considerable change in the demand of mesh typology in the local construction industry. It is very interesting and noteworthy to mention that the use of the traditional C503 mesh has been decreasing with each passing year, while the use of B503 and A503 meshes is growing on a yearly basis.

The wide range of C503 mesh in a number of lengths available from stock does not allow us to hold a wide range of lengths of other types of meshes such as B503 and A503 meshes. Therefore, customers are kindly requested to plan and pre-order their mesh requirements at least 48 hours in advance so that we can successfully produce their mesh to the required dimensions.

Our productive capabilities have now also extended to cover all types of meshes specified in BS 8666:

|

Reference

|

Longitudinal bars

|

Transverse bars

|

|

Nominal Bar Size

|

Pitch

|

Area

|

Nominal bar Size

|

Pitch

|

Area

|

Mass

|

|

mm

|

mm

|

mm2 /m

|

mm

|

mm

|

mm

|

kg/m2

|

|

Square Mesh

|

A393

|

10

|

200

|

393

|

10

|

200

|

393

|

6.16

|

|

A252

|

8

|

200

|

252

|

8

|

200

|

252

|

3.95

|

|

A193

|

7

|

200

|

193

|

7

|

200

|

193

|

3.02

|

|

A142

|

6

|

200

|

142

|

6

|

200

|

142

|

2.22

|

|

Structural Mesh

|

B1131

|

12

|

100

|

1131

|

8

|

200

|

252

|

10.9

|

|

B785

|

10

|

100

|

785

|

8

|

200

|

252

|

8.14

|

|

B503

|

8

|

100

|

503

|

8

|

200

|

252

|

5.93

|

|

B385

|

7

|

100

|

385

|

7

|

200

|

193

|

4.53

|

|

B283

|

6

|

100

|

283

|

7

|

200

|

193

|

3.73

|

|

Long Mesh

|

C785

|

10

|

100

|

785

|

6

|

400

|

70.8

|

6.72

|

|

C636

|

9

|

100

|

636

|

6

|

400

|

70.8

|

5.55

|

|

C503

|

8

|

100

|

503

|

6

|

400

|

49

|

4.51

|

|

C385

|

7

|

100

|

385

|

6

|

400

|

49

|

3.58

|

|

C283

|

6

|

100

|

283

|

6

|

400

|

49

|

2.78

|

|

Wrapping Mesh

|

D98

|

5

|

200

|

98

|

5

|

200

|

98

|

1.54

|

High Ductility and Seismic Mesh

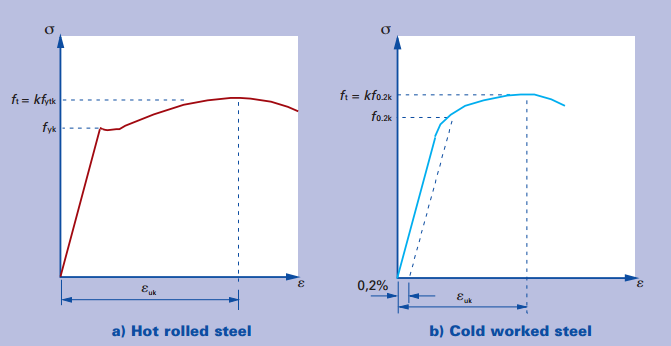

Our meshes are fashioned from High Ductility Hot Rolled Steel and certified to MSA EN 1992-1-1:2004 Quality B500C, thus carrying the same mechanical features of steel reinforcement bars. High ductility steel has high elongation, anti-seismic properties.

Mesh produced from high ductility hot rolled wire has superior quality characteristics than that produced from cold drawn wire. This is owed to the intrinsic advantages in its chemical composition. In the below illustration, one can clearly see the higher ductility properties of hot rolled steel in comparison with the conventional cold worked steel. It is also important to note that Grade B500C and B500B can only be achieved using hot rolled steel.

Identification

HD Vibro Mesh can be easily identified with our exclusive tagging system. A sticker is attached to each individual sheet, each with the description of the mesh type produced and the distinguishable standard to which it conforms.

Our latest investment should make supplies of electro-welded steel wire mesh increasingly efficient, with a broader range of solutions to the local construction sector.

If you would like to know more about our innovative welding line, how it works and the way it can benefit your company and its future projects, contact us today for more information.

Remember to follow us on Facebook and Twitter.