When it comes to choosing the right industrial flooring, there are a multitude of solutions to choose from. The first step in specifying the correct flooring system is asking the right questions. One of the most important factors to consider, first and foremost, is what the final surface needs to resist. It is also useful to ask questions such as: Is it a high-traffic environment? Do you use heavy equipment? If so, what kind of heavy equipment? How heavy is the footfall in the zone? Will the surface encounter water or moisture on a continuous basis? Are high heat or temperature extremes a factor? Does your area require chemical resistance?

These are crucial considerations that need to be kept in mind when selecting the right flooring system for your business. Knowing these requirements will help us determine what properties and characteristics the flooring system needs to provide.

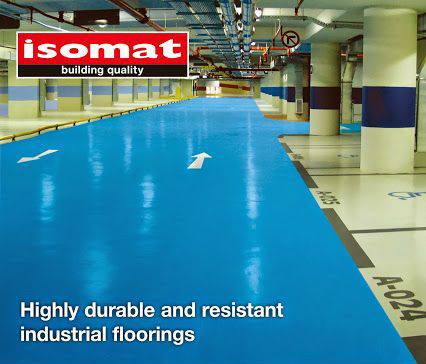

Industrial Floors

Industrial floors can serve a variety of trades such as general manufacturing, healthcare, pharmaceutical, chemical processing, food and beverage to hospitality, transportation, education, office and public spaces environments. Traditionally, the industrial floor has always been constructed using cast in-situ concrete, leaving the floor as exposed concrete, or possibly polishing the concrete to improve its surface resistance and durability.

Important properties of quality industrial floorings

Durability: epoxy and resin floors are tougher and more robust than concrete or any other material. Moreover, they have a longer life span and are cheaper to maintain and repair since they can be restored or replaced without the need for demolitions.

Seamless: these are floors without seams, gaps, ridges or joints. They are a lot more sanitary and easier to maintain.

Abrasion and impact resistance: having the ability to withstand heavy traffic and heavy equipment, these can take extraordinary loads and resist great surface impacts.

Slip-resistance: provide a safer working environment for the pedestrian user.

Chemical-resistance: weathering spills, splashes and stains, resistance to heavy metals, alkalis and acids, oil stains.

Installation speed: epoxy and resin floors can be installed as quickly as two days, reducing the disturbance to your business.

Appearance requirements: resin floors come in an assortment of finishes and colours from high gloss, to smooth or textured finishes.

Quick to clean: minimising the need to use chemicals and water usage to keep them clean. The surface strength also means that unlike concrete floors, the surface itself will not create dust.

Thermal shock-resistance: protecting floors from cracking due to extreme temperature or temperature fluctuations.

Anti-static (ESD): protecting your employees and equipment against electro-static discharge.

Choosing the right team

Determining the right solution and specifications for your flooring requirements is futile, unless the application is carried out with good quality products, and executed by skilled and experienced installers. It is important to seek a supplier / manufacturer who can provide a complete product cycle for the specification given, and it is equally important to commission a qualified (and ideally certified) installer for the works.

JMV is a reputable supplier of industrial flooring materials, delivering all the necessary know-how whilst ensuring nothing less than high quality and pristine results. To find out more about our solutions contact us to book an appointment.

Be sure to follow us on Facebook and Twitter.